Product Description

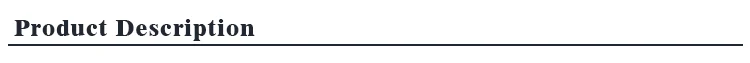

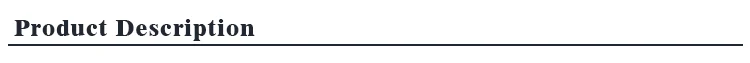

Communication tower consists of tower body, platform, lightning rod, ladder, antenna support and other steel components, and by hot galvanized anti-corrosion treatment, mainly for microwave, ultrashort wave, wireless network signal transmission and transmission.

|

Height

|

From 3 m to 30 m

|

|

Suit for

|

Airport ,seaport ,plaza, stadium , square, highway, street way etc

|

|

Shape

|

Conoid , Multi-pyramidal, Columniform,polygonal or conical

|

|

Material

|

Usually Q345B/A572,minimum yield strength>=345n/mm2

Q235B/A36,minimum yield strength>=235n/mm2

As well as Hot rolled coil from Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, to ST52-

|

|

Lamp power

|

20 W- 400 W (HPS/MH)

220V (+-10%) /50Hz

|

|

Tolerance of the dimension

|

+- 2%

|

|

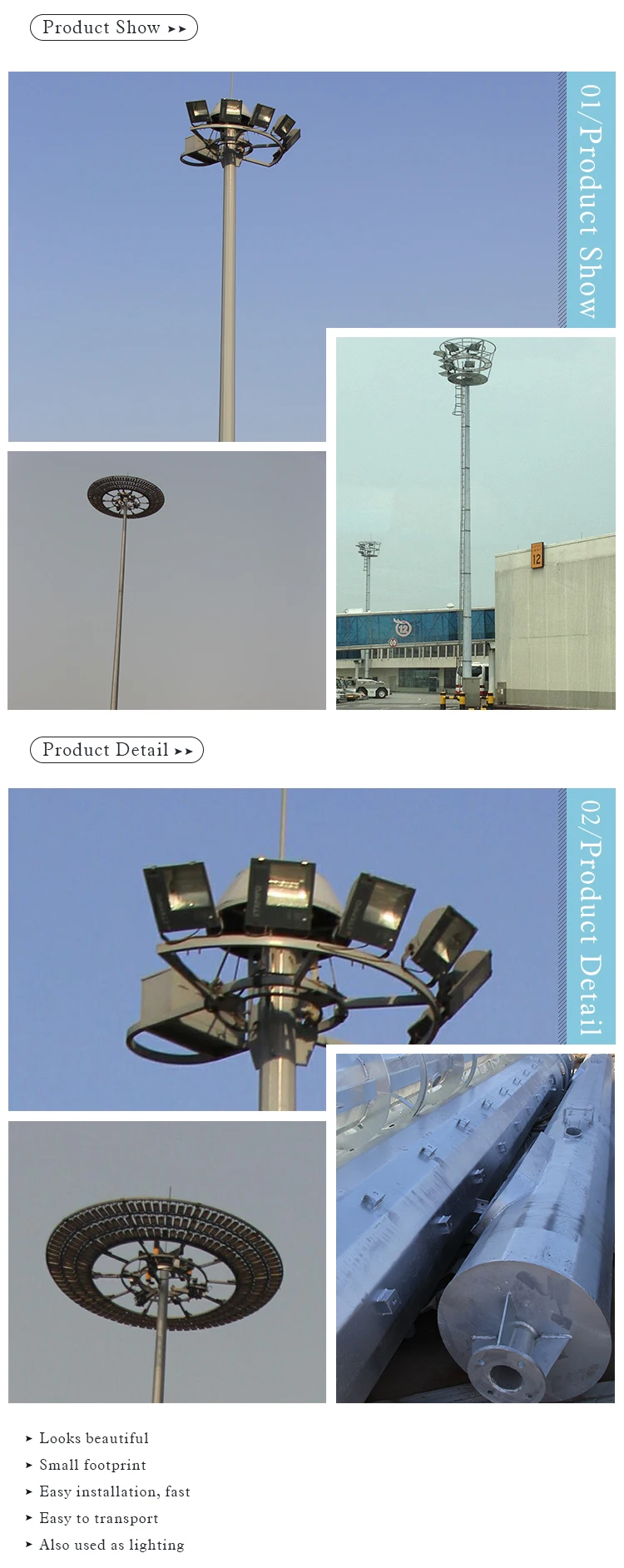

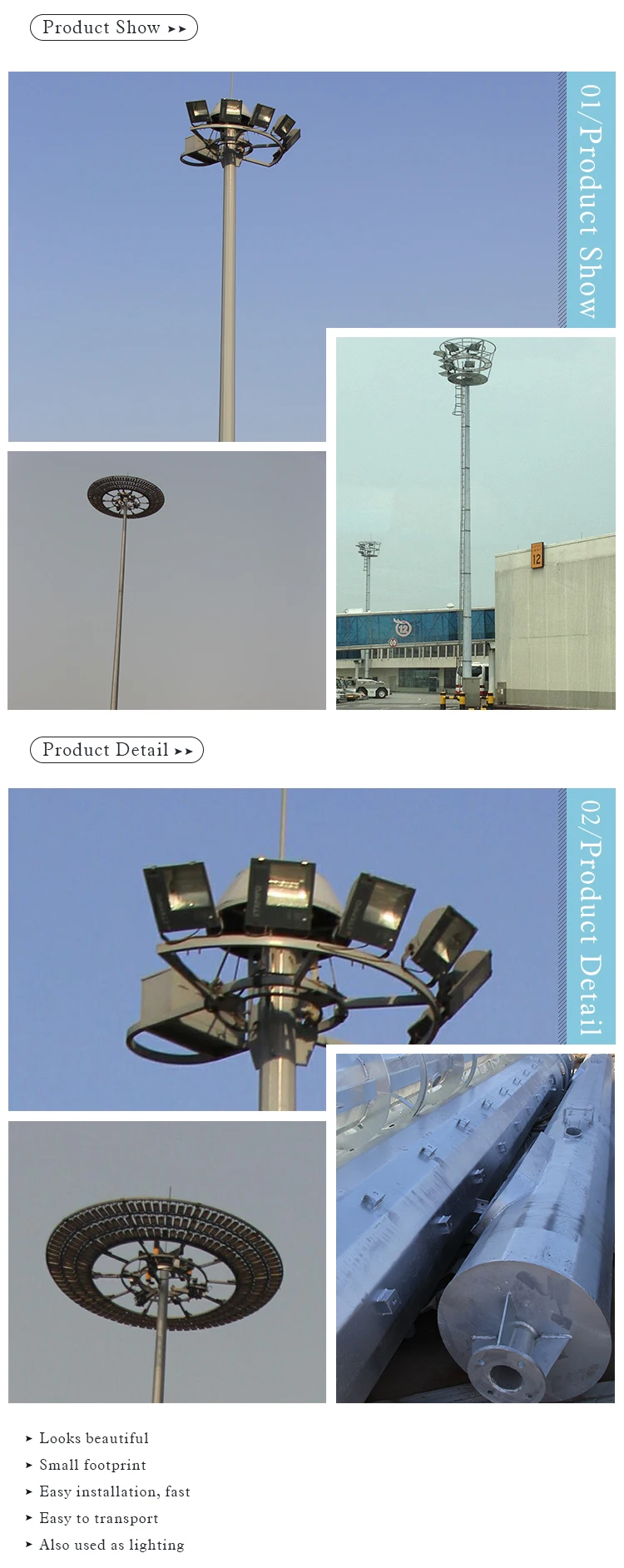

Optical assembly of lighting fixture

|

IP 65

|

|

Electroshock resistant protective grade

|

Grade Ⅰ

|

|

The casing anti-corrosion performance

|

Class Ⅱ

|

|

Working atmosphere of lighting fixture

|

-35 °C~+45

|

|

Surface treatment

|

Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required.

|

|

Joint of Poles

|

Insert mode ,innerflange mode ,face to face joint mode .

|

|

Design of pole

|

Against earthquake of 8 grade

|

|

Wind Speed

|

160 Km/Hour

|

|

Minimum yield strength

|

355 mpa

|

|

Minimum ultimate tensile strength

|

490 mpa

|

|

Max ultimate tensile strength

|

620 mpa

|

|

Standard

|

ISO 9001

|

|

Length of per section

|

Within 14m once forming without slip joint

|

|

Welding

|

We have past flaw testing. Internal and external double welding makes the welding beautiful in shape

Welding Standard :AWS (American Welding Society ) D 1.1

|

|

Thickness

|

1 mm to 30 mm

|

|

Production Process

|

Raw material test → Cutting →Molding or bending →Welding (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages

|

|

Packages

|

Our poles as normal cover by Mat or straw bale at the top and bottom ,anyway also can following by client required , each 40HC or OT can loading how many pcs will calculation base on the client actually specification and data.

|

|

Style

|

Size and styles are variable as per customer request

|

|

|

Our Advantage

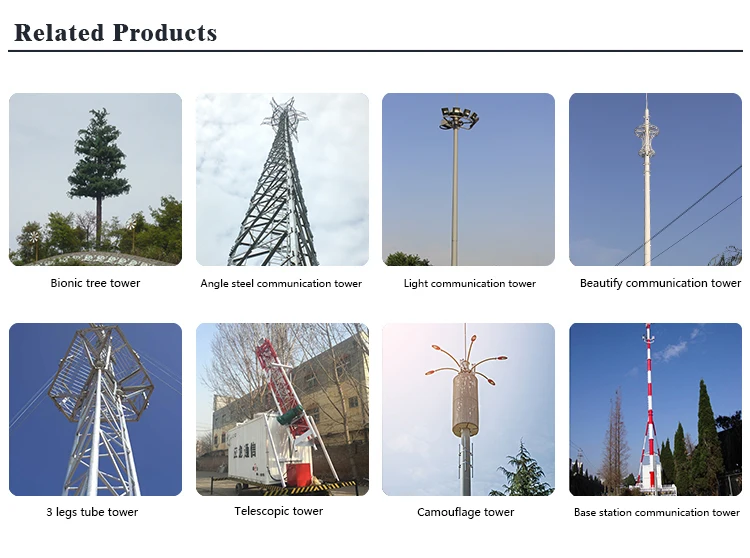

Our product categories: Communication tower (including three legged angle steel tower, four legged angle steel tower , single pole tower),Angle steel tower , Single- pipe tower , Steel tube tower),(Square steel tower, Triangular tower, Monopole),Microwave tower, Guyed tower(Guyed Masts), Self supporting tower , Guard tower, Bionic tower,Cell phone tower, lattice tower, Broadcast and TV tower, wind power tower, Power transmission tower ,Electric Power Series Towers (--Substation Structures,-Power Transmission Line Angle Steel Tower, -Power Transmission Line Steel Tube Towers), Street Light Pole Series, Technical Decoration Series Towers, Environment Series Towers etc.all kinds of towers.

Production Process

Before put into production, all the material must pass the chemical and physical analysis to make sure that they have met the requested strength and component. we have more than 15 inspection procedures from incoming raw material to finished products.